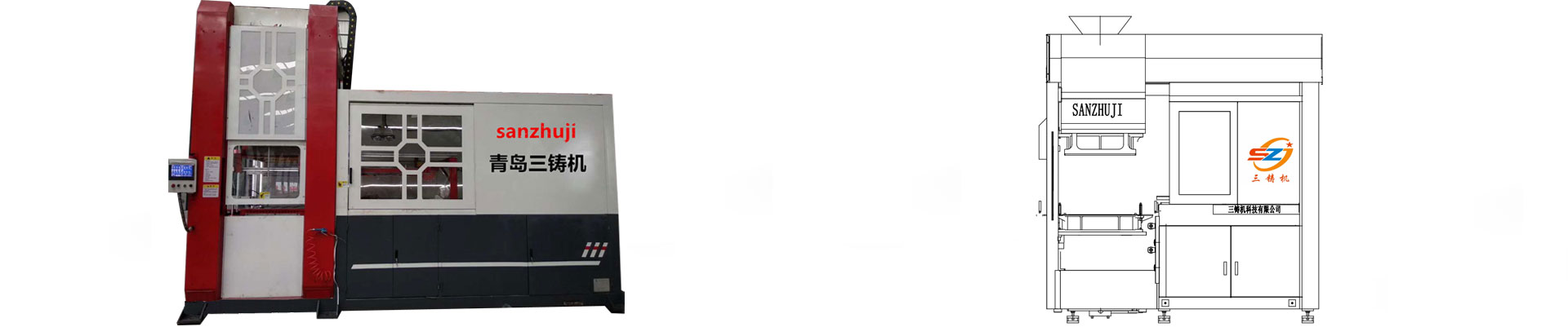

HS Green sand continuous sand mixer

HS Green sand continuous sand mixer

The green sand continuous sand mixer adopts PLC control. According to the uniformity of green sand mixing, it automatically adds coal powder, bentonite, and water. It uses a rotor motor. The comprehensive performance of the molding sand is good. The feed inlet is equipped with a screw feeder for auxiliary materials. Continuous sand mixing, the sand mixing efficiency can reach 30-80 T/H, the bottom of the sand mixing cage is equipped with a discharge port, which simplifies the transportation and storage process of the sand in the sand processing link.Product Introduction

The continuous green sand blender includes a feed bin with a new and old sand bin, a bentonite bin and a coal dust bin above the feed opening, respectively equipped with a screw feeding device. There is a water inlet on the side wall of the feed bin, and the PLC control unit is connected to a moisture detector, which can realize the online detection of the moisture contained in the old and new sand before mixing; after the human-machine control interface is pre-set for each raw material parameter, the PLC control unit will analyze and calculate to control the operation of the water pump inverter, the bentonite screw feeder inverter and the coal powder screw feeder inverter to realize the operation of water, bentonite and coal powder to the churn cage. The continuous online real-time quantitative addition of water, bentonite and pulverized coal to the stirrer cage, with a rotor shaft below the feed bin, the rotor shaft connected to a screw feed motor, the rotor shaft is provided with a first spiral conveying blade, a mixing rotor blade is provided at one end of the said rotor shaft, the mixing rotor blade is provided with a feed bin at the feed port, the feed bin is provided with a secondary water filling port, a housing is provided below the feed bin, four grinding mechanisms are provided inside the housing, a fifth rotor is provided below the grinding mechanism, the fifth The fifth rotor is connected to the sand mixing motor, the fifth rotor is equipped with a second spiral conveying blade, the fifth rotor is equipped with a second spiral conveying blade, the output port of the second spiral conveying blade is connected to the discharge bin, the discharge bin is equipped with a sixth rotor, the sixth rotor is connected to the rotor motor. Under the cage, there is a return bin with discharging mechanism, which is convenient to transport the mixed sand to the next production process.

Under the condition of achieving the same function, the continuous mixing function of this equipment changes the traditional intermittent sand mixing method, and also simplifies the process of sand transfer and storage in the sand processing link, making the whole sand processing process more concise and the equipment layout more compact.